Protecting machine safety and operational reliability with OEM-approved processes

Machine relocation is one of those industrial activities where mistakes rarely show themselves immediately. A machine may restart, appear stable, and even run production after relocation only to develop issues such as accuracy loss, vibration, abnormal wear, or repeated breakdowns weeks later. In most such cases, the problem is not movement or transportation. It lies in how the machine was handled in relation to OEM standards.

Every industrial machine is engineered with specific tolerances, load paths, and operating logic. When relocation activities fail to respect these parameters, the machine’s internal balance is disturbed. Our approach to machine relocation is built around strict adherence to OEM-approved processes, ensuring that machine safety, performance, and long-term reliability are preserved throughout the relocation lifecycle.

OEM Standards: The Engineering Intent Behind Every Machine

OEM standards are often mistaken for basic instruction manuals. In reality, they represent the engineering intent of the machine manufacturer, developed through design validation, material behavior studies, load analysis, and real-world operational feedback.

These standards govern not only how a machine operates but also how it should be dismantled, lifted, transported, reinstalled, aligned, and recommissioned. They account for internal stresses, precision component sensitivity, and structural behavior under non-operational conditions. When followed correctly, they ensure the machine continues to perform exactly as designed even after being relocated.

Why Adherence to OEM Standards Matters During Relocation

Relocation introduces forces and conditions that machines are not exposed to during normal production. Improper dismantling, uncontrolled lifting, or incorrect reassembly can permanently alter machine geometry and internal alignment.

OEM standards help control these risks by clearly defining:

- Shutdown and isolation sequences

- Dismantling order to maintain structural stability

- Lifting points and load distribution

- Protection of precision components

- Alignment tolerances during reinstallation

Our relocation methodology is structured around these requirements, ensuring risks are controlled rather than corrected later.

Controlled Dismantling Based on OEM Guidelines

Dismantling is not simply about separating components—it is about preserving the machine’s internal integrity. OEM-defined dismantling procedures ensure that stress is not introduced into the frame or critical assemblies during disassembly.

We follow a disciplined approach that secures moving axes, protects precision elements, and maintains correct dismantling sequences. Each component is documented and identified to ensure accurate reassembly. Machines dismantled without such control often develop misalignment issues that cannot be fully resolved during installation.

OEM-Compliant Lifting and Handling

Many relocation failures originate during lifting. Every machine has a specific center of gravity and approved lifting points based on its internal construction. Deviating from these parameters can introduce permanent distortion.

By applying OEM-approved lifting practices, we ensure that loads are transferred safely, frames remain stress-free, and sensitive assemblies remain protected. This controlled handling plays a decisive role in preserving machine accuracy after relocation.

Transport Protection Aligned With Manufacturer Requirements

During transit, machines are exposed to vibration, moisture, and environmental changes. OEM standards define how machines should be secured and protected to prevent internal movement and surface degradation.

Our transport protection methods focus on stability and preservation, ensuring the machine arrives ready for precision reinstallation rather than corrective intervention.

Reinstallation That Restores Engineered Accuracy

Reinstallation is not about placing a machine it is about restoring its engineered condition. OEM requirements define strict tolerances for leveling, alignment, assembly sequence, and fastening methods.

By following these parameters during reinstallation, internal stresses are avoided and load distribution remains correct. Machines installed without such discipline often show early signs of vibration, tool wear, and dimensional inconsistency.

Alignment, Calibration, and Validation

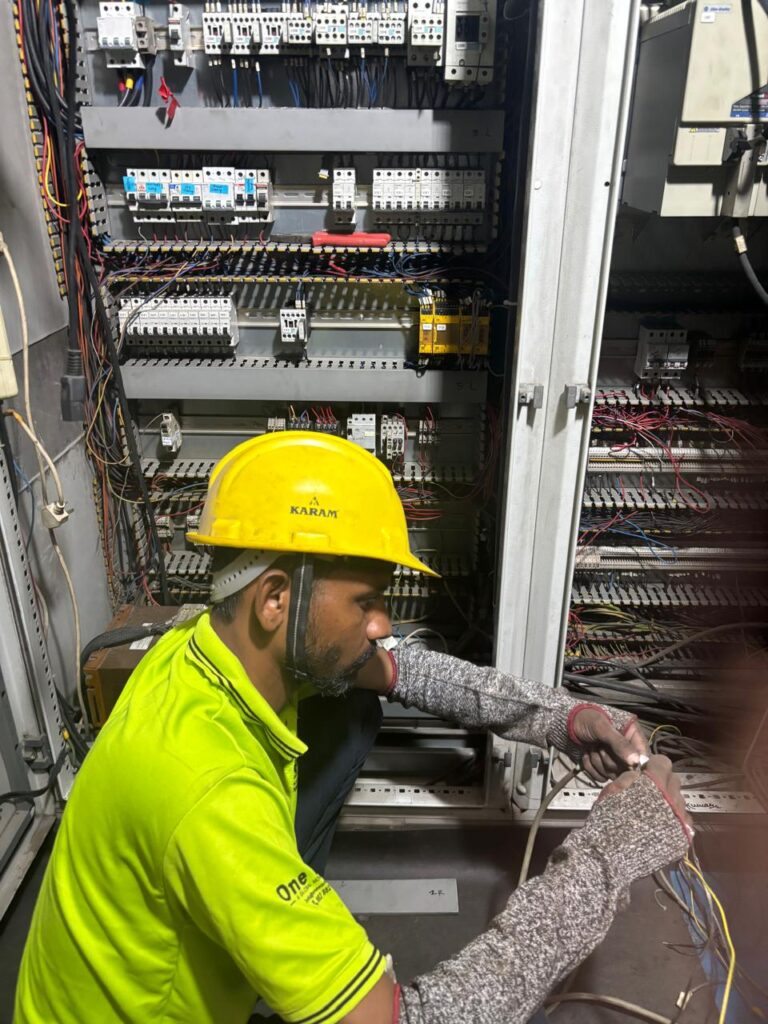

OEM compliance extends beyond mechanical installation. Final alignment, calibration, and functional testing confirm whether the machine is truly ready for production.

We carry out validation checks that ensure machine axes, spindles, safety systems, and control parameters operate within manufacturer-defined limits. This stage is essential for operational stability and consistent output.

Safety and Reliability Through Structured Execution

Machine safety systems are designed around specific mechanical and control conditions. Improper relocation can compromise guarding effectiveness, interlocks, and emergency response behavior.

By executing relocation in line with OEM standards, we ensure that machines operate within their designed safety envelope. This results in fewer breakdowns, predictable maintenance cycles, and stable production performance.

Protecting Warranty and Long-Term Value

Most manufacturers clearly state that relocation must follow approved procedures. Any deviation can affect warranty coverage and future support.

Our OEM-aligned execution protects equipment value, avoids warranty disputes, and ensures machines remain eligible for manufacturer service support.

Conclusion

OEM standards are not documentation formalities; they are the engineering rules that protect machine integrity. Every stage of machine relocation, from dismantling to recommissioning, must align with these standards to avoid long-term operational risks.

By approaching machine relocation as a controlled engineering process rather than a logistical task, we ensure faster stabilization, reduced downtime, and extended machine life. In complex industrial environments, professional execution guided by OEM standards defines the difference between temporary success and long-term reliability.