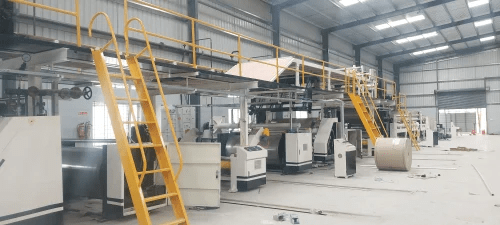

From unloading to testing how our team ensures flawless machine installation.

It’s a process that demands precision, planning, and teamwork at every stage. We handle each step of machine installation with care from unloading and positioning to final testing to make sure every piece of equipment runs safely, smoothly, and efficiently.

Here’s how our experts carry out a flawless machine installation process step by step.

1. Pre-Installation Planning and Site Assessment

Every successful installation begins with proper planning. Before the machine even arrives, our team studies its technical specifications including weight, dimensions, electrical requirements, and foundation needs.

We then conduct a site inspection to ensure everything is ready for installation:

- Checking floor strength and levelness to support heavy machinery.

- Verifying entry and access points for lifting or shifting equipment.

- Reviewing space layout, ventilation, and operator movement zones.

- Ensuring power supply, compressed air, and other utilities are properly positioned.

This initial stage helps us identify and fix potential challenges before they cause delays during the actual installation.

2. Safe Transport, Unloading, and Positioning for machine installation

The next stage is carefully moving the machine to its designated area. This is where we experienced rigging and handling team comes in.

We use the right combination of cranes, forklifts, and lifting gear based on the machine’s weight and structure. Safety is always the top priority every movement is coordinated under the supervision of our trained operators.

Once unloaded, the machine is placed near its foundation area and positioned for precise alignment. Our aim here is simple: zero damage and full control from start to finish.

3. Foundation, Leveling, and Anchoring

A strong foundation is the key to a stable and long-lasting installation. Our team first ensures that the base or foundation meets the required load and vibration standards. If needed, we make adjustments or reinforcements before placement.

After that, we proceed with:

- Leveling: Using precision tools like spirit levels or laser instruments to ensure perfect balance.

- Shimming and alignment: Correcting uneven surfaces for accurate positioning.

- Anchoring: Securing the machine to the floor using bolts or plates to prevent shifting during operation.

Proper leveling and anchoring are critical even a few millimeters of imbalance can lead to vibration, misalignment, and reduced performance.

4. Assembling and Connecting Components

Once the machine is in place, we move on to assembly and connection. Many industrial machines arrive in sections or with attachments like motors, conveyors, or guards. Our skilled technicians handle this step following OEM (Original Equipment Manufacturer) guidelines.

We connect:

- Electrical systems (main supply, control panels, sensors).

- Hydraulic and pneumatic lines for pressure and movement.

- Cooling and lubrication systems as per equipment design.

Every connection is double-checked for safety and accuracy. Loose wiring, wrong fittings, or poor lubrication can cause costly issues later our checks eliminate those risks before the machine goes live.

5. Precision Alignment and Testing

This is one of the most crucial steps in machine installation. Once the setup is complete, our technicians perform fine alignment to ensure every part is correctly positioned.

We use tools such as:

- Laser alignment systems

- Dial indicators

- Precision levels

These tools help achieve accurate alignment between shafts, couplings, and moving parts. If the machine has rotating or linear components, alignment ensures smooth motion and prevents premature wear or imbalance.

We also check for soft-foot conditions, ensuring that all mounting points rest evenly on the surface.

6. Trial Runs and Calibration – Machine Installation

Before handing over the machine, we perform several rounds of testing and calibration. This stage ensures the equipment runs exactly as intended by the manufacturer.

Our trial process includes:

- Dry runs without load to check movement and noise levels.

- Full load tests to monitor temperature, vibration, and output accuracy.

- Safety checks for emergency stops, interlocks, and alarms.

- Calibration of sensors, scales, and control systems to match OEM specs.

By the time we complete this stage, the client can be confident that the machine is ready for production with zero functional errors.

7. Final Inspection, Documentation, and Handover

After testing, our team carries out a final inspection to confirm that every connection, bolt, and wire is properly secured. We document all readings, including leveling measurements, alignment data, and calibration records.

Finally, we conduct a handover session with the client’s maintenance or production team. During this walkthrough, we explain:

- Basic operation and control features.

- Safety instructions.

- Preventive maintenance recommendations.

This ensures a smooth transition and complete understanding of the installed equipment.

Why Each Step Matters

Skipping even a small step in machine installation can lead to major consequences from early breakdowns to production delays.we understand that installation quality defines machine performance. That’s why our approach is built on:

- Safety: For both people and machinery.

- Accuracy: Every alignment and level reading matters.

- Accountability: Clear documentation and transparency with clients.

- Reliability: Machines that start right, run right, and last longer.

Conclusion

Machine installation is not just a technical task it’s a commitment to precision, safety, and performance. At Oneworld Logix, we combine skilled manpower, modern tools, and years of relocation experience to ensure every installation is done the right way, the first time.

Whether it’s part of a factory relocation, a machine shifting project, or a new equipment setup, we make sure your machines are not only moved but installed to perform at their best.