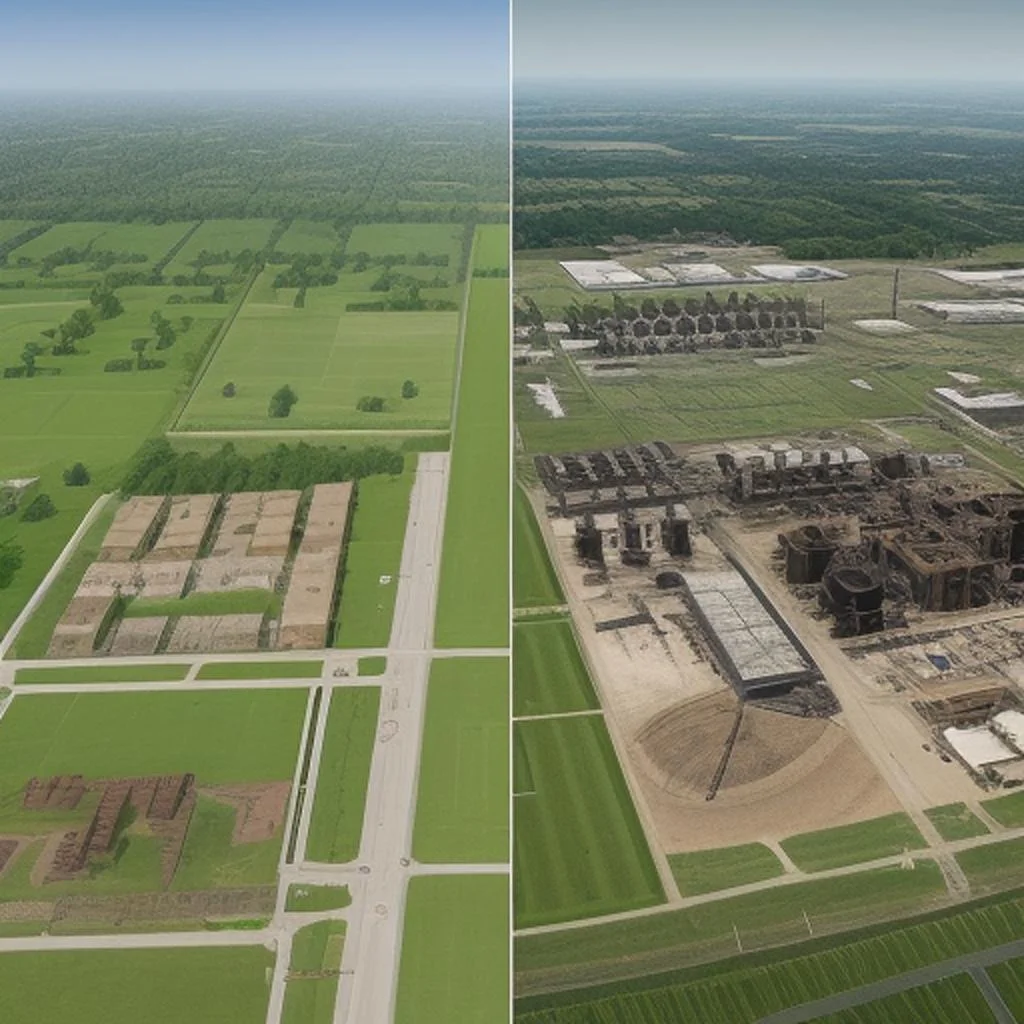

Explore the Pros and Cons of Greenfield vs Brownfield Each Approach to Make Smarter Industrial Relocation Decisions

Introduction

Relocating heavy or precision machinery is far more complex than moving office furniture. Every bolt, calibration, and load-bearing surface matters. When planning a machine‑shift project, you must decide whether to build a greenfield site fresh on undeveloped land or execute a brownfield retrofit upgrading an existing facility greenfield vs brownfield. This decision will drive your costs, timelines, risk of equipment damage, and long‑term scalability.

What Is a Greenfield Machinery Shift?

A greenfield machinery shift means constructing a brand‑new facility tailored to your machines’ exact specifications. From the floor pad thickness to overhead crane placements, nothing is left to chance.

Key Advantages

- Precision-Engineered Layout

– Design foundation pads, pit depths, and anchor points to OEM tolerances.

– Optimize clearance routes for loaders, forklifts, and crane booms. - Modern Handling Infrastructure

– Integrate built‑in rail systems, gantry cranes, and vibration‑dampening floors.

– Specify power distribution, air lines, and control cabinets exactly where needed. - Minimal Downtime for Future Upgrades

– Plan extra bays or modular extensions for additional machines.

– Embed sensors and monitoring systems during construction.

Common Drawbacks

- High CapEx for Civil Works

– Excavation, reinforced concrete, and specialized foundations add up.

– Custom power and compressed air lines increase initial costs. - Extended Project Duration

– Permitting, environmental studies, and full‑site construction can take 12–24 months.

– Delays in equipment delivery or contractor availability can push timelines further. - Regulatory Hurdles

– New builds typically require stricter inspections for load‑bearing, seismic compliance, and safety systems.

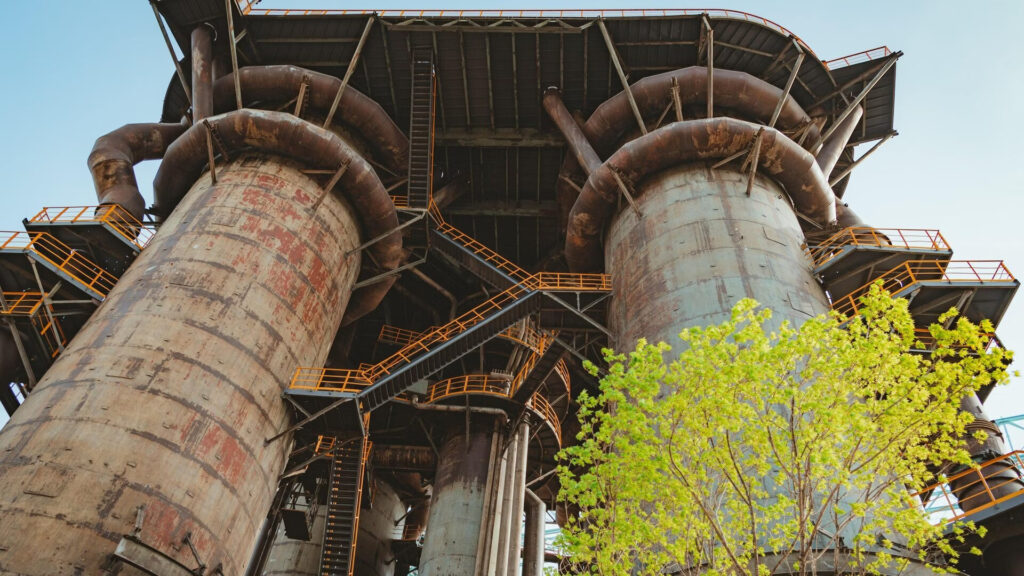

What Is a Brownfield Machinery Shift?

A brownfield machinery shift adapts an existing facility to house your equipment. It’s like retrofitting a house to install a new home theater—except with cranes, forklifts, and multi‑ton presses.

Key Advantages

- Lower Initial Investment

– Use existing floor slabs, roof structures, and utility feeds.

– Only upgrade areas directly impacted by the new machine footprint. - Shorter Setup Time

– Begin disassembly and installation as soon as structural inspections clear.

– If foundations are adequate, you can skip major civil works. - Familiar Site Conditions

– Existing drainage, power capacity, and access roads are already proven.

– The workforce often knows the site layout and safety protocols.

Common Drawbacks

- Structural Constraints

– Floor loads, ceiling heights, and bay widths may not meet new machine specs.

– Reinforcement or jack‑up systems might be needed for super‑heavy equipment. - Unforeseen Remediation

– Old oils or coolants in pits, asbestos in ceilings, or buried debris can halt progress.

– Environmental surveys and remediation add time and cost. - Integration Complexity

– Fitting advanced CNC machines or laser cutters into decades‑old power and HVAC systems may require custom substations or chillers.

Comparing Greenfield vs Brownfield: Machinery‑Specific Factors

| Factor | Greenfield | Brownfield |

|---|---|---|

| Equipment Fit | Custom‑designed foundations, exact tolerances | May need grout pads or shim adjustments |

| Transport & Rigging | Crane rails and lift points built‑in | Temporary cranes or external rigging needed |

| Downtime Impact | Can phase installation around production | May interrupt ongoing operations |

| Risk of Damage | Controlled environment, minimal unknowns | Hidden site issues can damage expensive kit |

| Scalability | Add bays or floors for future machines | Limited by existing bay dimensions |

Real‑World Example

Case Study: Precision Gearworks Ltd.

- Challenge: Relocate three 20‑ton CNC mills and two 50‑ton forging presses.

- Brownfield Retrofit Chosen: An adjacent, under‑utilized warehouse with sturdy 40 cm concrete slabs.

- Actions:

- Structural survey confirmed floor load capacity.

- Local crane company installed a temporary 100‑ton gantry system.

- Soil contamination near old oil pits required a 3‑week remediation.

- Precision grouting and laser alignment completed in 2 weeks.

- Results:

- Total downtime: 8 weeks (vs. 16+ months for greenfield).

- Overall cost: 55% of greenfield estimate.

- Machines commissioned within OEM tolerance specs.

A Step‑by‑Step Machinery Shift Framework

- Operational Blueprint

– Map machine footprints, service clearances, and load paths.

– Determine foundation and utility requirements from vendor documentation. - Site Feasibility

– Greenfield: Conduct geotechnical surveys and environmental assessments.

– Brownfield: Perform structural scans, contamination tests, and load‑capacity checks. - Cost & Risk Analysis

– Estimate foundation, rigging, and calibration costs.

– Include potential remediation, custom rigger fees, and overtime for shutdowns. - Timeline Planning

– Greenfield: Build in lead times for permits, concrete curing, and vendor schedules.

– Brownfield: Schedule around existing production, plan off‑hours rigging to minimize disruptions. - Execution & Validation

– Use laser trackers and dial indicators to confirm alignment.

– Perform trial runs, balancing, and vibration tests before handover.

Conclusion

For heavy or precision machinery, the greenfield vs brownfield choice is not just about land or buildings it’s about ensuring your equipment arrives, installs, and operates within exact tolerances while minimizing downtime and cost.

- Choose greenfield if you need a purpose‑built facility with no legacy constraints and have the time and budget for a full‑scale build.

- Opt for brownfield when speed, cost savings, and leveraging existing infrastructure outweigh the risks of retrofit challenges.

By following a structured decision framework grounded in machine‑specific assessments and vendor requirements you’ll select the approach that keeps your machinery precise, your production on schedule, and your budget intact.